Press release -

Minebea Intec at Anuga FoodTec India 2025: Focus on Packaging Quality

Minebea Intec will present its latest weighing and inspection technologies at Anuga FoodTec India 2025 from August 20–22 at the Bombay Exhibition Centre, Mumbai. Under the event motto "Passion for Precision", the company highlights solutions that help the packaging industry meet key requirements: efficiency, compliance and consumer safety. At Stand M22 in Hall 4, visitors can discover systems designed for increasing demands in automation, traceability and sustainable materials.

At the forefront of Minebea Intec’s new offerings is the X-ray inspection system Identus, designed to detect metal, glass, stone, bone, and dense plastic contaminants with unparalleled accuracy. Its 15" intuitive touchscreen, product teach-in functionality, and ability to verify mass distribution, fill levels, and product completeness make it a game-changer for packaged food safety.

Capable of inspecting sachets, trays, cartons, and even metallized packs at belt speeds up to 40 m/min, Identus features high-resolution imaging (0.4 mm) and robust safety mechanisms including E-Stop, key switch, and interlocks. With connectivity via Modbus, Ethernet, USB, and digital I/Os, Identus integrates seamlessly into modern production lines. For packaging industry professionals, Identus offers clear benefits: it helps minimise product recalls by reliably detecting contaminants in sealed or opaque packaging, supports compliance with HACCP and IFS standards, and ensures consistent product presentation thanks to completeness checks. Its compact design and hygienic construction make it ideal for space-limited environments – even on fast-paced packaging lines with frequent product changeovers.

Compact Metal Detection Excellence

In addition to X-ray inspection systems, Minebea Intec will also be presenting its portfolio of metal detectors. A special highlight: The Freefall Metal Detector Vistus® RS. It offers exceptional sensitivity to ferrous, non-ferrous, and stainless-steel contaminants in gravity-fed product flows. Its IP65-rated stainless steel housing, adaptive digital filtering, and dual-channel signal analysis enable reliable detection even in compact production spaces. A user-friendly touchscreen and seamless integration options make Vistus® RS ideal for food, pharma, and plastics industries focused on product purity and compliance.

For manufacturers in the packaging industry, Vistus® RS helps reduce material waste by reliably identifying contaminated product, with quick setup during format changes. The space-saving design is particularly advantageous for vertically integrated packaging lines where footprint and flexibility are critical. In addition to the freefall version, the Vistus® series is also available as a pipeline system or for use on search belts – offering the right detection solution for a wide range of packaging line configurations, from pumped products to packaged goods on conveyors.

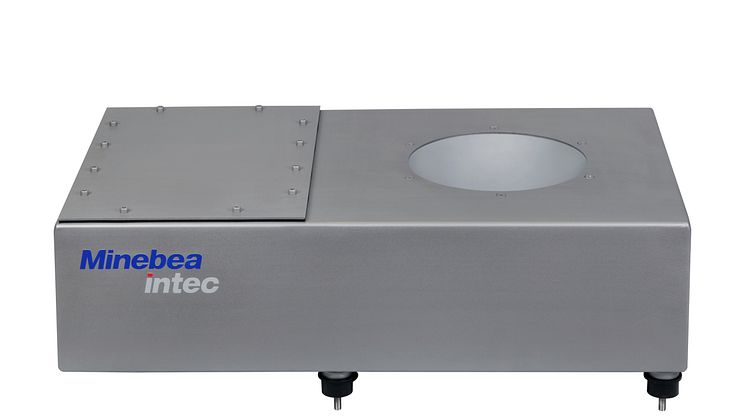

Precision Checkweighing Made Simple

Inspection technologies are not only relevant for the identification of foreign objects. Checkweighers are essential to ensure, among other things, that products are complete and have the correct weight. Designed for versatile weighing environments, the checkweigher Essentus® Advanced delivers precise weight checking with up to 150 products per minute. Featuring an automatic learning mode, real-time weight visualization, and robust stainless steel build, this dynamic checkweigher is perfect for hygiene-sensitive sectors. The system includes customizable conveyor configurations, 10” touchscreen, multi-language interface, and role-based access control. With full support for RS232/485, Profibus, Profinet-IO, and USB data transfer, it ensures operational efficiency and traceability. Classifying operations with 3-way or 5-way sorting, integrated fault alerts, and reject mechanisms round out its capabilities.

Especially for packaging industry customers, Essentus® Advanced offers decisive benefits: It safeguards compliance with net content regulations by reliably detecting underfilled or overfilled packages, ensures seamless integration into automated packaging lines, and reduces giveaway – a key factor in cost-sensitive production environments. The system’s modular conveyor options also make it suitable for a wide range of packaging formats, from flowpacks to boxes and pouches.

Visit us at Anuga FoodTec India 2025

Minebea Intec offers a comprehensive range of high-quality weighing and inspection solutions, including industrial scales, checkweighers, metal detectors, load cells, silo scales, and advanced X-ray. The company supports customers throughout the entire project cycle - from consultation to commissioning – backed by expert guidance and powerful software that enhances process efficiency.

Visit Minebea Intec at Anuga FoodTec India 2025, 20th to 22nd August, Hall 4 Booth M22, Bombay Exhibition Centre, Mumbai, for live demos and expert interaction. “With our future-oriented weighing and inspection solutions, we support our industrial customers in producing safely and efficiently”, said Mr. Mohan Bhat, Global Director R&D & Managing Director India, Minebea Intec. “We look forward to the trade fair and will be happy to respond to individual enquiries.”

Topics

Categories

Minebea Intec is a leading global manufacturer of industrial weighing and inspection technologies. Headquartered in Hamburg, Germany, the company offers products and services that have stood for innovation, performance and reliability for more than 150 years. The product portfolio includes high-resolution platform scales, load cells, hopper and silo scales, checkweighers, metal detectors, X-ray and visual inspection systems as well as intuitive software solutions. Over 1,000 employees at 18 locations increase the precision and efficiency of industrial customers' weighing and production processes. A network of over 200 partners in 72 countries complements the global player's sales and service locations. The high performance and distinctive German quality are reflected in the brand promise "the true measure".

Minebea Intec is part of the MinebeaMitsumi Group, a leading supplier of high-precision production parts such as ball bearings and motors as well as high-quality electronic components such as sensors, antennas and IoT solutions. The Group, which is headquartered in Tokyo and has around 84,000 employees worldwide, reported consolidated net sales of 1,522,703 million yen (approx. 9.3 billion euros) for the 2025 financial year.