Press release -

How formulation software makes your pharmaceutical production safer and more efficient

ProRecipe XT® is the optimal solution from Minebea Intec, a leading global manufacturer of weighing and inspection technologies, for companies in the pharmaceutical industry in particular. The software combines scales and software into a powerful unit to map manual dosing processes and fulfils the high requirements for precision, process reliability and regulations such as GxP. This benefits not only production companies with demanding recipes but also system integrators who want to expand their portfolio with a powerful recipe management system.

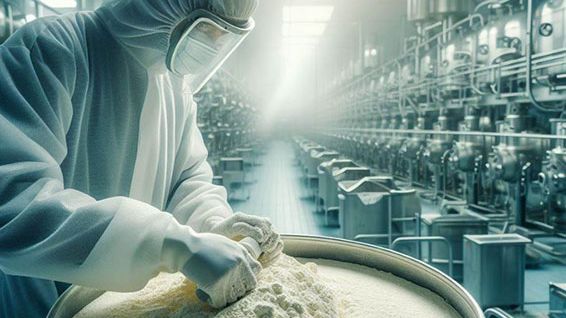

The production hall is filled with a concentrated atmosphere. All the raw materials for the upcoming order are ready. An employee takes a quick look at the screen: The exact quantities for the next batch have already been calculated. A targeted scan of the label of the first raw material immediately opens a clear weighing screen. The employee precisely batches the material until the colour changes on the screen: the target quantity has been reached. Thanks to the ProRecipe XT®software solution from Minebea Intec, the entire process runs smoothly - from exact weighing of the ingredients to automatic documentation. What used to be laboriously and error-prone recorded on paper is now a digitally controlled and documented process that improves data integrity. "With ProRecipe XT®, we enable our customers not only to digitalise their production processes but also to make them significantly safer and more efficient," explains Lars-Henrik Bierwirth, Global Product Manager at Minebea Intec. "Thanks to the complete traceability and precise control of all process parameters, we are setting new standards in production safety."

Efficiency and precision combined

ProRecipe XT®ensures precise dosing and transparently documents all steps - from small batches to complex multi-component recipes. A typical application example is the production of pharmaceuticals, where numerous ingredients have to be processed in different quantities. Here, ProRecipe XT® ensures that each ingredient is batched exactly and weighing errors are avoided. Thanks to the interface to existing ERP systems, order and batch data can be transferred automatically. Once dosing is complete, ProRecipe XT® returns the weighing data and consumption quantities directly. This saves time, minimises input errors and ensures an up-to-date stock overview at all times.

In regulated industries such as the pharmaceutical industry, where the highest standards of data integrity and GxP compliance apply, ProRecipe XT® is the ideal solution. The software was developed in accordance with the recommendations of GAMP5 and offers comprehensive reporting and audit trail functions that fully fulfil the requirements for computerised systems in accordance with the FDA. "For reasons of data integrity, our customers in the pharmaceutical sector often want to digitally record the entire manufacturing process - not just the dosing steps. With ProRecipe XT® , we make this possible with digital manufacturing instructions that can be integrated directly into recipes," explains Bierwirth. A pharmaceutical manufacturer that processes different active ingredients in small batches can thus ensure that each ingredient precisely meets the specifications and that the entire production process remains fully traceable - a decisive advantage for safety and efficiency in this industry. "With ProRecipe XT® , our customers minimise the risk of process errors and guarantee that all batches are consistently produced to the same standards and specifications," adds Bierwirth.

In the pharmaceutical industry, where there are often long lead times for the implementation of IT projects, ProRecipe XT® offers the necessary flexibility with its modular licence system. "Our solution is so scalable that both small and large companies can benefit," emphasises Bierwirth. "The user-friendliness and adaptability of ProRecipe XT® make it the perfect choice for any production environment."

The perfect interplay of hardware and software

One thing is crucial for the successful use of ProRecipe XT® : high-quality weighing solutions. Minebea Intec offers a broad portfolio of durable, highly accurate load cells, industrial scales and electronic weighing systems that can be seamlessly integrated into ProRecipe XT® . The comprehensive services - from software and weighing solutions to commissioning and qualification - come from a single source. Where necessary, Minebea Intec provides support with individual adaptations in order to offer customised solutions for specific customer requirements - a holistic service approach that impresses.

The smooth interaction of hardware and software brings structure and precision to every process step, from batch recording to the complete documentation of all ingredients. Thanks to the intuitive operation of ProRecipe XT® , users always have an overview, even with complex recipe processes and are guided through the process step by step. This creates a focussed working atmosphere in which the operator can concentrate fully on batching - while the software takes care of the rest.

5,127 characters, incl. spaces

Topics

Categories

Minebea Intec is a leading manufacturer of industrial weighing and inspection technologies. Headquartered in Hamburg, the company offers products and services that have stood for innovation, performance and reliability for more than 150 years. Its product portfolio includes platform scales, load cells, vessel and silo scales, checkweighers, metal detectors, X-ray inspection systems and user-friendly software solutions. More than 1,000 employees at 18 sites worldwide increase the precision and efficiency of industrial customers' weighing and production processes. A network of over 200 partners in 71 countries complements the sales and service locations of the global player. The performance strength and distinctive German Quality are reflected in the brand promise "the true measure".

Minebea Intec is part of the MinebeaMitsumi Group, a comprehensive precision components manufacturer that integrated a wide range of cutting-edge technologies, from ultra-precision machining technologies, such as miniature and ball bearings, which boast the No. 1 global market share, to motors and sensors. The Tokyo-headquartered group, which employs over 92,000 people worldwide, reported consolidated net sales of 1,292,203 billion yen (approximately 9.17 billion euros) for the 2023 financial year.