Press release -

Food Safety in Chocolate Production

November 2024 – During the pre-Christmas season, increasing efficiency and ensuring food safety in chocolate production are essential topics that determine success and trust. If foreign bodies, such as contaminated raw materials, packaging residues, or anything as a result of human error, end up in chocolate products and are not detected and removed before distribution, it could lead to costly and damaging product recalls. Learn in this expert article how advanced weighing and inspection technologies help produce chocolate products safely and efficiently.

Christmas is a time associated with chocolate delights in all forms, from festively wrapped pralines to chocolate Santas and Advent calendars. However, during the peak season, when production lines run around the clock, manufacturers face particular challenges. Ensuring food safety in chocolate production is a must – not only to protect the brand but also to safeguard consumers and maintain customer trust in these coveted holiday products. To meet these demands and enhance efficiency simultaneously, companies rely on effective weighing and inspection technologies from Minebea Intec, which demonstrably fulfill the high standards of the industry.

High-Level Chocolate Production Safety – A Practical Example

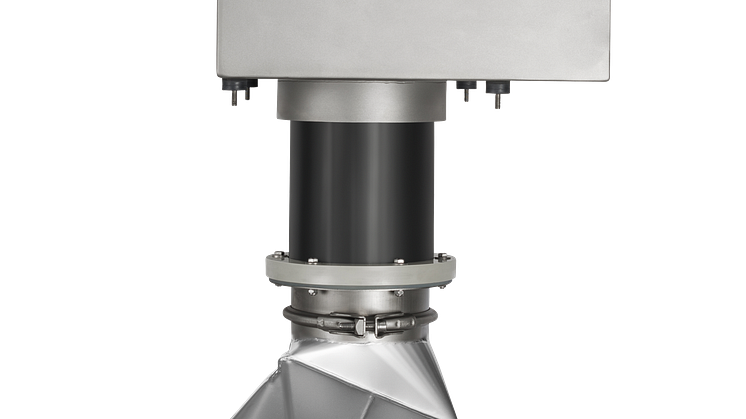

An impressive example of advanced foreign object detection in the confectionery industry is the case of Ludwig Weinrich GmbH & Co. KG, a renowned chocolate manufacturer that chose Minebea Intec’s metal detector Vistus®. Ludwig Weinrich's decision was driven by its stringent quality and safety standards. With the metal detector Vistus®, the company reliably protects its products from metallic contaminants, ensuring the highest food safety standards.

“Our metal detector Vistus® stands out due to its high sensitivity and flexibility to adapt to various production conditions,” explains Linus Dellweg, Product Manager at Minebea Intec. “Especially during the Christmas season, when production is at full capacity, a robust yet precise solution like Vistus® is indispensable.” This efficiency in detecting foreign bodies, combined with its adaptability to different product variants, ensures safe and uninterrupted production, even at high throughput.

The benefits for Ludwig Weinrich are clear: by using the metal detector Vistus®, the company has significantly enhanced product safety while optimising its production processes. With the capability to detect even the smallest metallic foreign objects, thus preventing production stoppages, Vistus® provides added value, especially critical during intensive Christmas production. Additionally, the system's high adaptability allows for seamless integration into existing production lines without requiring extensive modifications.

Even More Precision: The Metal Detector Mitus® with MiWave Technology

The technological advancement at Minebea Intec continues. For even more demanding applications, the company introduced the metal detector Mitus® with innovative MiWave technology in 2023. This advanced technology operates with multiple simultaneous high-frequency waves, enabling even more precise detection across a wide range of product types. “With MiWave, we can reliably monitor even challenging products with significant product effects,” emphasises Dellweg. This technology shines particularly with chocolate products, whose composition and consistency vary greatly.

For manufacturers like Ludwig Weinrich, implementing the metal detector Mitus® means not only increased product safety but also a significant boost in production efficiency. Thanks to MiWave technology’s high detection accuracy, false rejects are minimized, reducing the need for manual intervention and increasing line speed – a decisive advantage during the busy Christmas production period. Mitus® thus helps manufacturers maintain smooth, uninterrupted production processes, enhancing overall productivity during peak times while ensuring product quality. Both metal detection solutions from Minebea Intec are available as conveyor, free-fall, or pipeline versions.

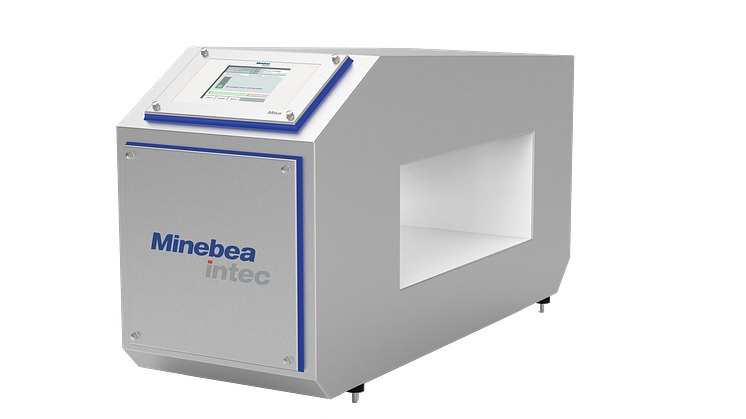

Minebea Intec as a Partner of the Chocolate Industry

In addition to metal detectors, Minebea Intec offers high-quality weighing solutions specifically tailored to the needs of the chocolate industry. Metal detectors are also available in compact combination versions with checkweighers that automatically and precisely check each product’s weight in real-time. This allows food producers to ensure their products meet regulatory requirements and quality standards – achieving maximum efficiency and safety throughout the process. “We don’t limit ourselves to manufacturing technology,” emphasizes Dellweg. “We see ourselves as partners to the industry, supporting our customers with comprehensive expertise and customised solutions, even for specific challenges in food production.” This means Minebea Intec provides tailored solutions and maintains close collaboration with manufacturers to ensure safe production, even during peak seasons. As a result, the Christmas season remains a worry-free time of indulgence – allowing consumers to enjoy sweet treats with peace of mind.

5,145 characters, including spaces

Topics

Categories

Minebea Intec is a leading global manufacturer of industrial weighing and inspection technologies. Headquartered in Hamburg, Germany, the company offers products and services that have stood for innovation, performance and reliability for more than 150 years. The product portfolio includes high-resolution platform scales, load cells, hopper and silo scales, checkweighers, metal detectors, X-ray and visual inspection systems as well as intuitive software solutions. Over 1,000 employees at 18 locations increase the precision and efficiency of industrial customers' weighing and production processes. A network of over 200 partners in 71 countries complements the global player's sales and service locations. The high performance and distinctive German quality are reflected in the brand promise "the true measure".

Minebea Intec is part of the MinebeaMitsumi Group, a leading supplier of high-precision production parts such as ball bearings and motors as well as high-quality electronic components such as sensors, antennas and IoT solutions. The Group, which is headquartered in Tokyo and has around 84,000 employees worldwide, reported consolidated net sales of 1,402,127 million yen (approx. 8.9 billion euros) for the 2024 financial year.